How to Ensure Workflow Consistency with strapping machine service

Wiki Article

The Importance of Regular Strapping Machine Service for Smooth and Reliable Packaging Processes

Routine strapping machine service plays an important function in making sure reliable product packaging operations. Neglecting maintenance can result in unexpected malfunctions and lowered performance. By proactively resolving possible issues, organizations can improve both machine efficiency and product quality. Recognizing the value of normal service is fundamental for preserving functional performance. Nonetheless, numerous business ignore this crucial aspect. What factors should be thought about to establish a reliable maintenance approach?Recognizing Strapping Machines and Their Role in Packaging

Although strapping machines may seem like simple gadgets, they play an essential function in the product packaging industry by making sure the protected packing of products. These machines use plastic or steel bands around packages, supplying stability during transport and storage space. By developing tight, dependable seals, strapping machines help prevent damages and keep item stability. Their effectiveness adds to quicker packaging processes, allowing organizations to fulfill increasing demand without sacrificing top quality. Furthermore, strapping machines can be incorporated right into automated systems, enhancing process and reducing labor costs. The convenience of these machines makes them appropriate for different sectors, from making to circulation, making sure that products stay intact throughout the supply chain. Inevitably, strapping machines are crucial to effective product packaging procedures.Typical Issues Arising From Lack of Upkeep

When strapping machines are not correctly kept, a number of common concerns can occur that impede their performance and dependability. Frequent malfunctions can happen due to worn-out elements, causing pricey downtimes and interfered with manufacturing routines. Additionally, inappropriate tensioning may lead to weak seals, compromising plan honesty. Dirt and particles buildup can harm machine sensing units and moving components, creating irregular operation and raised wear. Disregarded lubrication can lead to friction and getting too hot, more damaging internal systems. Operators might additionally deal with obstacles when adjusting settings on poorly maintained machines, leading to irregular product packaging outcomes - strapping machine service. On the whole, an absence of maintenance can seriously impact the performance and performance of strapping machines, inevitably influencing the entire product packaging processAdvantages of Normal Strapping Machine Service

Routine strapping machine service offers substantial advantages that add to operational success. By making certain improved equipment long life and improved operational performance, organizations can minimize the likelihood of unexpected failures. Ultimately, this positive method lowers downtime risks, cultivating a much more reliable production setting.Enhanced Tools Durability

Preserving a strapping machine via regular service significantly contributes to its overall longevity. Regular assessments and upkeep assistance determine deterioration prior to they escalate right into considerable problems, consequently prolonging the life of essential parts. By dealing with small mistakes quickly, operators can avoid pricey repair work and substantial downtime that can arise from disregard. On top of that, routine maintenance guarantees that all mechanical components operate successfully, lowering the risk of machine failure throughout operations. This positive strategy not only boosts the strapping machine's longevity yet likewise cultivates a more secure working environment. Eventually, purchasing normal service converts to a much more reputable machine that consistently satisfies production demands, protecting the integrity of the packaging procedure for years ahead.Improved Operational Efficiency

Regular service of strapping machines significantly improves functional performance by making sure that all components work at their ideal. Normal maintenance reduces the danger of mechanical failures, enabling for consistent and reputable performance. Properly maintained machines operate at optimum speeds, maximizing throughput and decreasing the moment required for packaging procedures. This effectiveness not only helps fulfill manufacturing targets but additionally contributes to a smoother workflow, as operators can depend on the devices without interruptions. In addition, routine servicing identifies possible issues early, enabling restorative activities to be taken prior to they intensify. As an outcome, services experience structured procedures, which can result in enhanced efficiency and enhanced total efficiency in product packaging jobs. Normal service is crucial for preserving an efficient packaging environment.Reduced Downtime Dangers

Reliable service schedules for strapping machines considerably lower the threats of downtime connected with unexpected mechanical failings. Normal upkeep checks aid recognize possible issues before they intensify, guaranteeing that machines operate successfully and dependably. By addressing wear and tear, lubrication requirements, and electric parts proactively, businesses can avoid costly disturbances in their product packaging procedures. Furthermore, set up maintenance enhances the life-span of strapping machines, reducing the frequency of replacements and linked expenses. The decrease in unexpected downtime not just boosts productivity yet also boosts staff member spirits, as workers can rely on equipment that operates seamlessly. Eventually, dedicating to routine service builds a durable procedure, safeguarding against disruptions and allowing companies to satisfy production targets constantly.Key Parts to Screen Throughout Routine Service

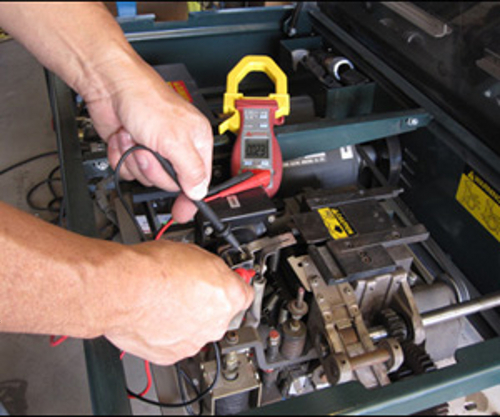

While carrying out routine service on a strapping machine, it is crucial to monitor a number of essential components to secure peak efficiency and long life. The tensioning system ought to be looked for appropriate operation, assuring that straps are safely tightened up without causing damages. The securing device has to be inspected for wear and tear, as any breakdown can jeopardize the honesty of the product packaging. Furthermore, the feed system calls for attention to assure consistent and smooth strap shipment. It is additionally vital to take a look at electrical connections, as damaged or loose electrical wiring can cause operational failures. Ultimately, lubrication levels ought to be examined to avoid friction-related problems, promoting reliable machine function. On a regular basis keeping an eye on these elements will add substantially to the machine's general reliability.Establishing a Maintenance Schedule

A properly designed upkeep timetable plays a crucial duty in ensuring the ideal procedure of a strapping machine. It should include normal evaluations, cleaning, and part substitutes based on the supplier's recommendations. Developing a regularity for these jobs-- such as once a week, regular monthly, or quarterly-- can help preemptively address potential problems. Furthermore, recording each maintenance activity enhances responsibility and enables tracking the machine's performance in time. When tailoring the schedule, Operators needs to also think about the production volume and certain functional needs. By focusing on regular service, companies can lessen downtime, prolong the machine's life-span, and preserve regular packaging top quality. Ultimately, a detailed maintenance routine is necessary for optimizing strapping machine performance and dependability in packaging processes.Choosing the Right Service Provider

Just how can one assure the selection of a suitable service providerfor strapping machine maintenance? It is necessary to study prospective suppliers completely. Examining their experience, market credibility, and know-how in strapping machine modern technologies can offer beneficial understandings. Additionally, customer testimonials and testimonials commonly expose the top quality of service and dependability.Next, take into consideration the provider's certification and training programs, which show their dedication to preserving high criteria. It is likewise crucial to inquire concerning their feedback times for service telephone calls and the availability of click to find out more spare parts.

Lastly, acquiring numerous quotes permits for a comparison of pricing and service packages, ensuring a knowledgeable choice. Inevitably, the right company will enhance efficiency and decrease downtime in packaging operations.

The Long-Term Influence of Consistent Machine Care

Consistent machine care significantly influences the durability and efficiency of strapping machines, as regular maintenance helps determine prospective issues before they escalate. By executing a structured service schedule, businesses can minimize unexpected downtimes and expensive fixings. This proactive strategy not only guarantees peak operating yet likewise enhances the high quality of packaging, leading to enhanced customer satisfaction. In time, well-maintained machines show much better performance, causing minimized operational prices and enhanced productivity. In addition, a culture of routine care fosters employee self-confidence in devices integrity, advertising a smoother operations. Ultimately, the lasting impact of constant machine care translates into substantial savings and an affordable side in the packaging industry, making it an indispensable method for organizations seeking lasting development.

Regularly Asked Inquiries

Just how Usually Should I Change Strapping Machine Components?

Strapping machine parts must be replaced every 1,000 to 2,000 hours of operation, depending on use strength. strapping machine service. Normal assessments can help determine certain needs, making certain peak performance and lessening downtime from equipment failure

Can I Perform Upkeep on My Own?

Yes, one can do upkeep on their own, offered they have the necessary abilities and understanding. Nonetheless, seeking advice from the maker's guidelines is necessary to ensure appropriate treatments are followed and safety and security is kept.What Indicators Indicate I Required Immediate Service?

Signs indicating the requirement for prompt service consist of unusual sounds, irregular strapping stress, frequent error messages, visible endure parts, or unforeseen shutdowns (strapping machine service). Dealing with these problems quickly assures operational effectiveness and prevents additional damageJust How Does Weather Affect Strapping Machine Performance?

Climate condition can substantially affect strapping machine efficiency. Severe temperatures, humidity, and dampness levels might create materials to broaden or contract, influencing stress and seal stability, resulting in possible operational issues and minimized product packaging efficiency.

What Is the Average Cost of Routine Service?

The ordinary expense of routine service for strapping machines typically varies from $150 to $500, relying on the machine's intricacy and the company's competence, ensuring peak efficiency and long directory life of the equipment.Regular strapping machine service plays a crucial function in guaranteeing reliable product packaging procedures. Routine service of strapping machines significantly boosts operational effectiveness by making certain that all parts function at their finest. While performing routine service on a strapping machine, it is vital to keep an eye on a number of click here for info essential parts to secure peak performance and durability. By focusing on regular service, businesses can minimize downtime, extend the machine's life-span, and keep constant packaging top quality. Consistent machine care greatly influences the durability and performance of strapping machines, as normal maintenance helps determine potential problems prior to they intensify.

Report this wiki page